Drying

Drying is believed to be one of the oldest methods of food preservation. While there is little recorded history of dehydration of foods, sun-drying and the smoking of foods over a hot fire are mentioned in the Bible. Samples of foods which were discovered within the last few years were believed to have been dried in Jericho 4,000 years ago. An important part of the diet of American Indians was smoked fish and meat. Dried corn was an important part in the diet of colonial America.

In 1917 the United States Department of Agriculture published the first instruction booklet on drying foods at home. Many of the methods described would not be considered safe today. During World Wars I and II many foods were dehydrated in an effort to develop lightweight, nutritious, stable foods for the military.

Today there has been a renewed interest in drying as a method of home food preservation. Both counter top dehydrators and portable convection ovens are being promoted for use in home drying.

Many claims are currently being made by promoters of these appliances about the nutrient content, keeping quality, and energy use involved in preparing home dried foods. Only a small number of research articles have been published in this area. Those published indicate that the nutritional content of home dried foods is not superior to that of foods canned or frozen at home. Home drying is used most successfully by persons preparing small quantities of food for camping or back-packing trips.

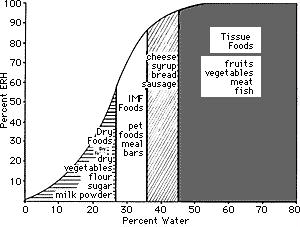

Drying preserves food by lowering the amount of water or moisture in the food material. This is necessary to prevent microbial growth and chemical reactions which can only occur when enough water is present in the food. Equilibrium Relative Humidity (ERH) is a term used to describe the availability of the water to the chemical environment and microorganisms present in foods. The equilibrium relative humidity or percent ERH scale varies from zero to 100. Figure 1 illustrates the meaning of percent ERH.

Figure 1 Percent Water |

Fresh tissue foods, such as meat, vegetables, and fruit products, have an ERH close to 100 percent. An ERH level this high means that the water present in these foods is available for rapid growth of microorganisms leading to deterioration and spoilage of the food. By drying foods it is possible to lower the percent ERH. As the percent ERH is lowered, the growth of microorganisms slows or ceases since the water is no longer as available for their growth. This occurs at an ERH of 60 percent. Therefore, all foods must be dried to below 60 percent ERH and kept in a dry environment to be shelf stable from microbial growth because microorganisms cannot survive below this ERH level.

Although drying foods to about 60 percent ERH prevents microbial growth, certain chemical reactions caused by enzymes can still occur which result in spoilage and deterioration of the product. Fresh produce contains many different enzymes which cause loss of color, loss of nutrients, and flavor changes in dried vegetables and fruits. These enzymes must be inactivated to prevent such reactions from taking place.

Enzymes in vegetables are inactivated by the blanching process. Blanching is

the exposure of the vegetables to boiling water or steam for a brief period of

time. Blanched vegetables when dried will have better color and flavor than

unblanched. For

blanching times consult the tables below.

The major problem associated with enzymes in fruits is the development of brown colors and loss of vitamins A and C. Fruits are not blanched like vegetables because the blanching process gives fruits a cooked flavor. Instead, the enzymes in fruits are inactivated by using chemical compounds which interfere with deteriorative chemical reactions. The most common control chemicals used are sodium bisulfite and ascorbic acid (Vitamin C). Ascorbic acid may be used in its pure form or in chemical mixtures of ascorbic acid and other compounds such as "Fruit Fresh." Food grade sodium bisulfite, sodium sulfite or sodium metabisulfite may also be used for pretreatment of fruit. Individuals sensitive to sulfites, particularly some asthmatics, should use ascorbic acid.

Both counter top dehydrators and portable convection ovens can be used on a 110/120 volt general purpose circuit (15 AMP). The food dehydrators draw 525-800 watts; the convection ovens draw about 1500 watts and should not be used on the same general household circuit with other heating appliances such as a coffee maker or toaster. This may be an important consideration in view of the fact that convection ovens used for drying may be running for many hours.

Food dehydrators and convection ovens differ in their range of temperature settings and available square feet of drying space. The range of temperature settings for dehydrators as a low of 85° to 110° F up to a high of 140° to 145° F. The range for convection ovens has a low of 140° to 175° F up to a high of 500° F. Food dehydrators are usually made to handle more racks and, therefore, have more square feet of drying space than portable convection ovens. The appliances require 18-24 inches of counter space and vary in height from 10-16 inches. The height is a consideration if it is to fit on a counter with cabinets above.

The Icons below will guide you to the other Food Drying Pages |